About Us

LOGY LASERTECH, S.L.U. is a company based in Galicia (Spain), specialized in the manufacture of laser systems and machines with the highest performance for the most demanding industries, such as: automotive, aeronautics, machinery, electronics, military, pharmaceutical, etc.

Our products are the best choice for companies that they are looking for solutions based on the application of laser technology with the best quality / price ratio on the market. Furthermore, all our laser systems and machines are manufactured in accordance with current European legislation and regulations.

OUR TECHNOLOGICAL AREAS

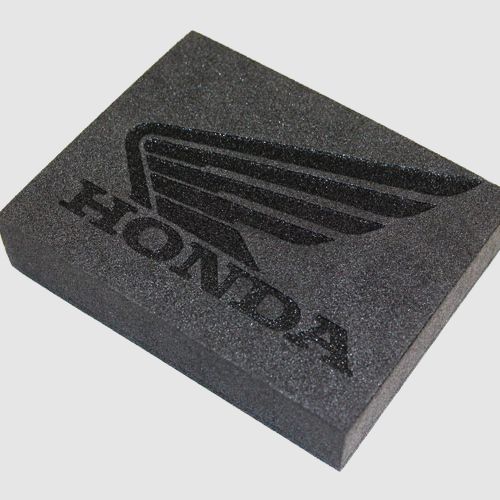

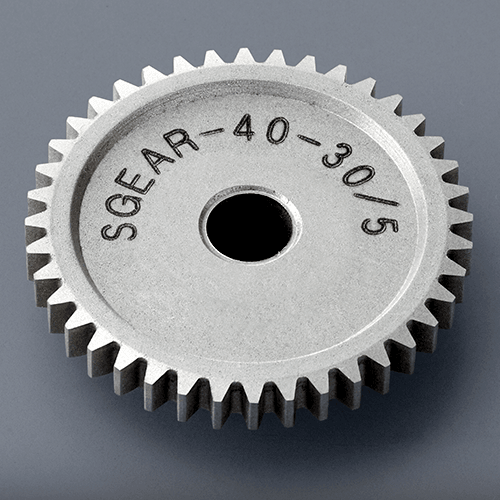

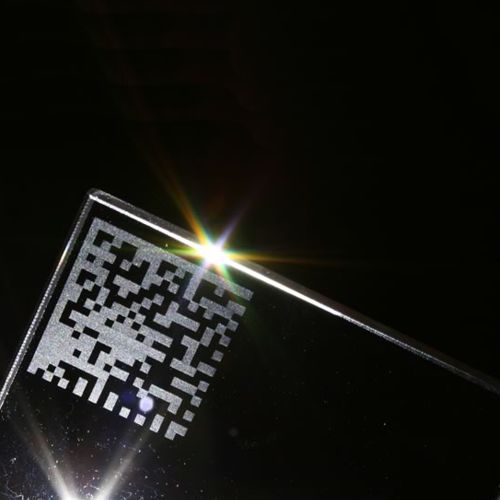

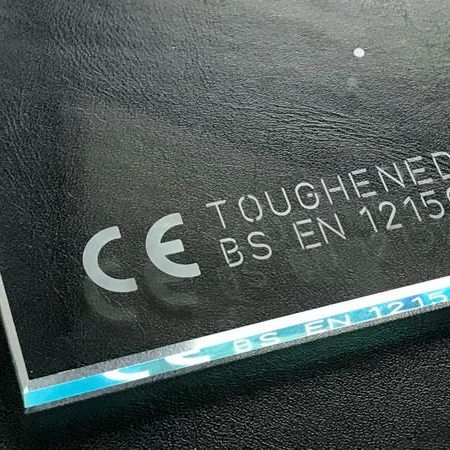

Laser Marking

LASERLOGY offers you a wide range of laser marking systems and machines with multiple power variants and all common industry technologies (CO2, Fiber, UV, etc). These systems are suitable for marking processes such as etching, engraving, ablation, tempering, coloring or foaming. LASERLOGY laser markers process, besides metals, many other materials such as plastic, acrylic, stone, glass, ceramics, paper, leather, carton, wood and other organic materials. All our laser markers can be easily integrated into your system or production line due to their compact size and multiple control possibilities.

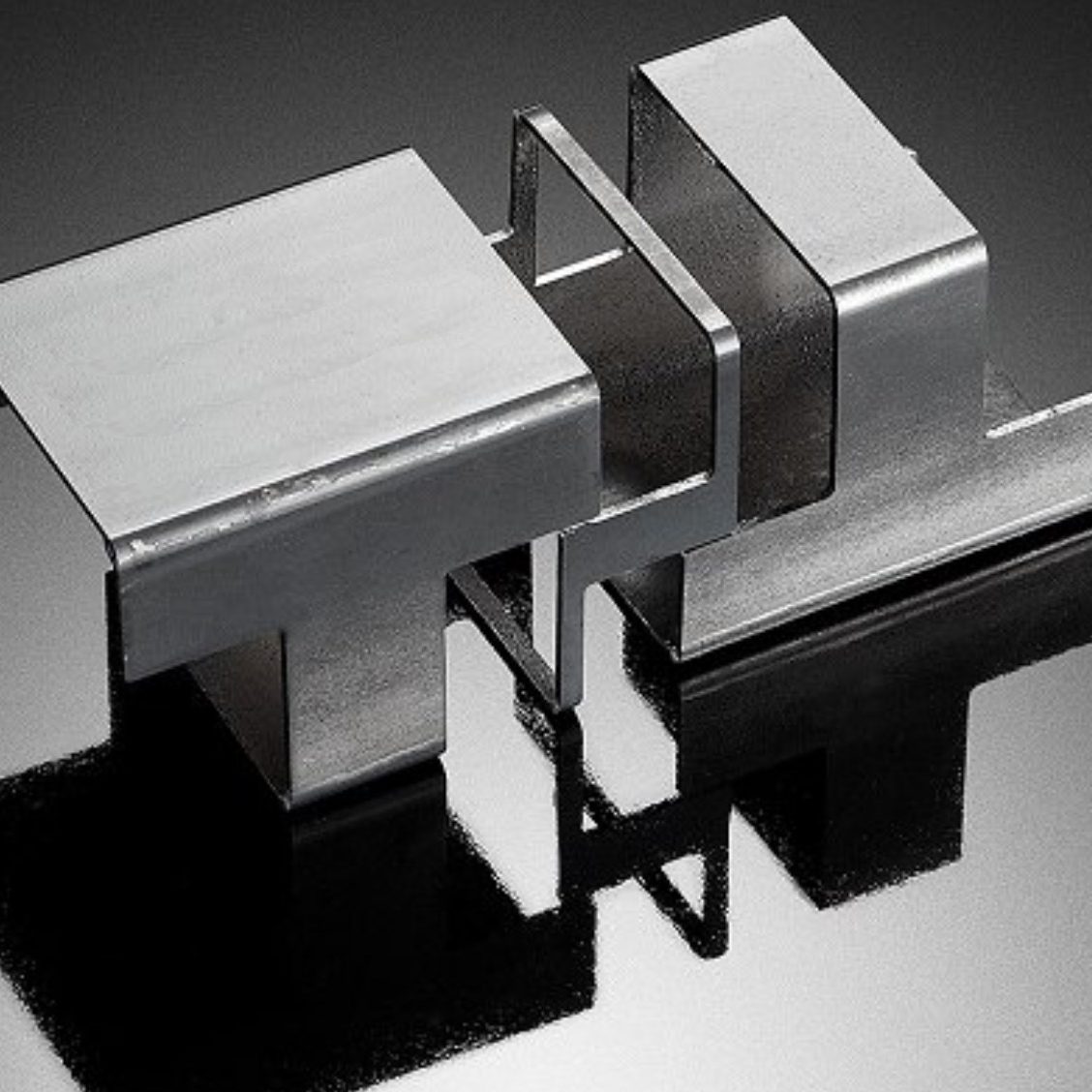

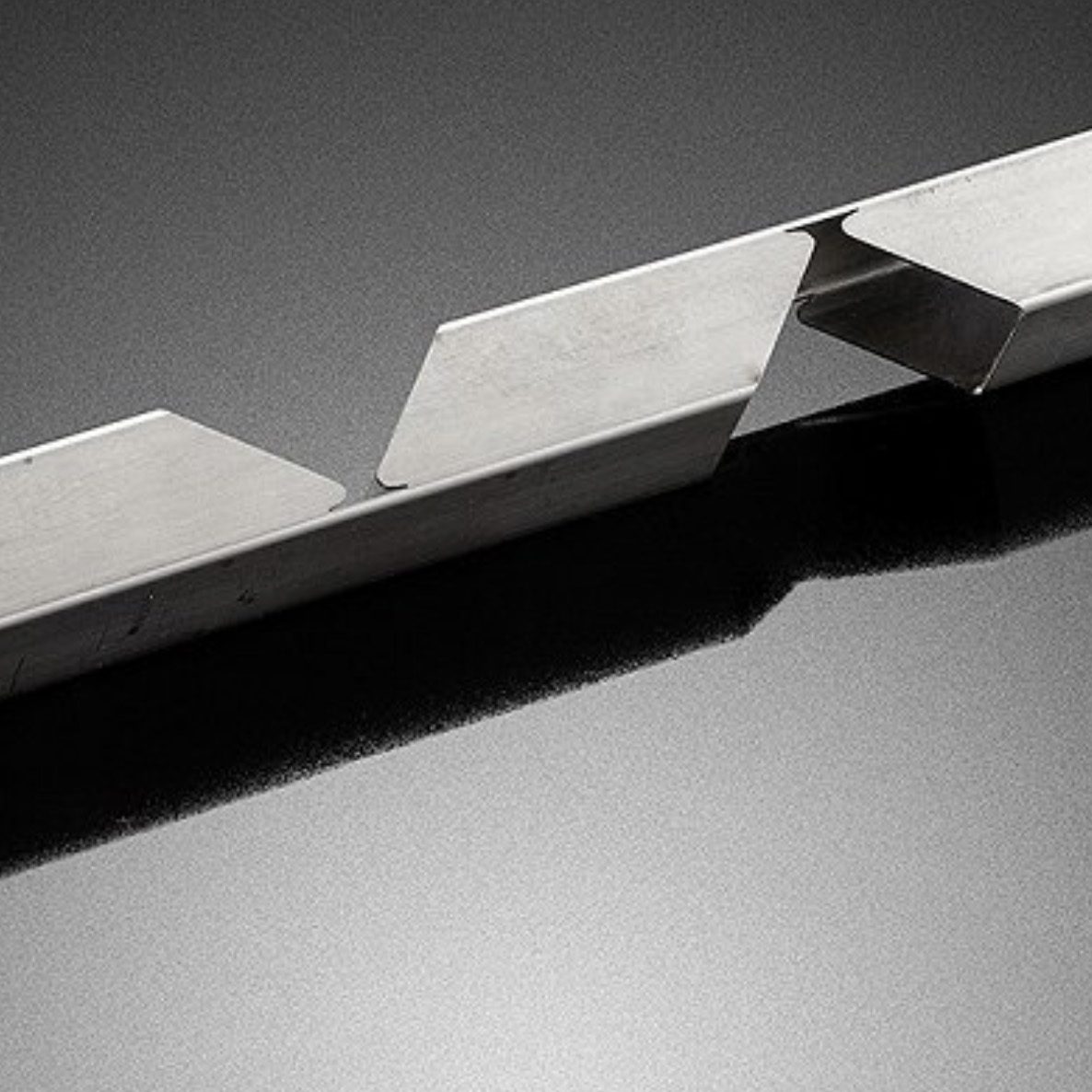

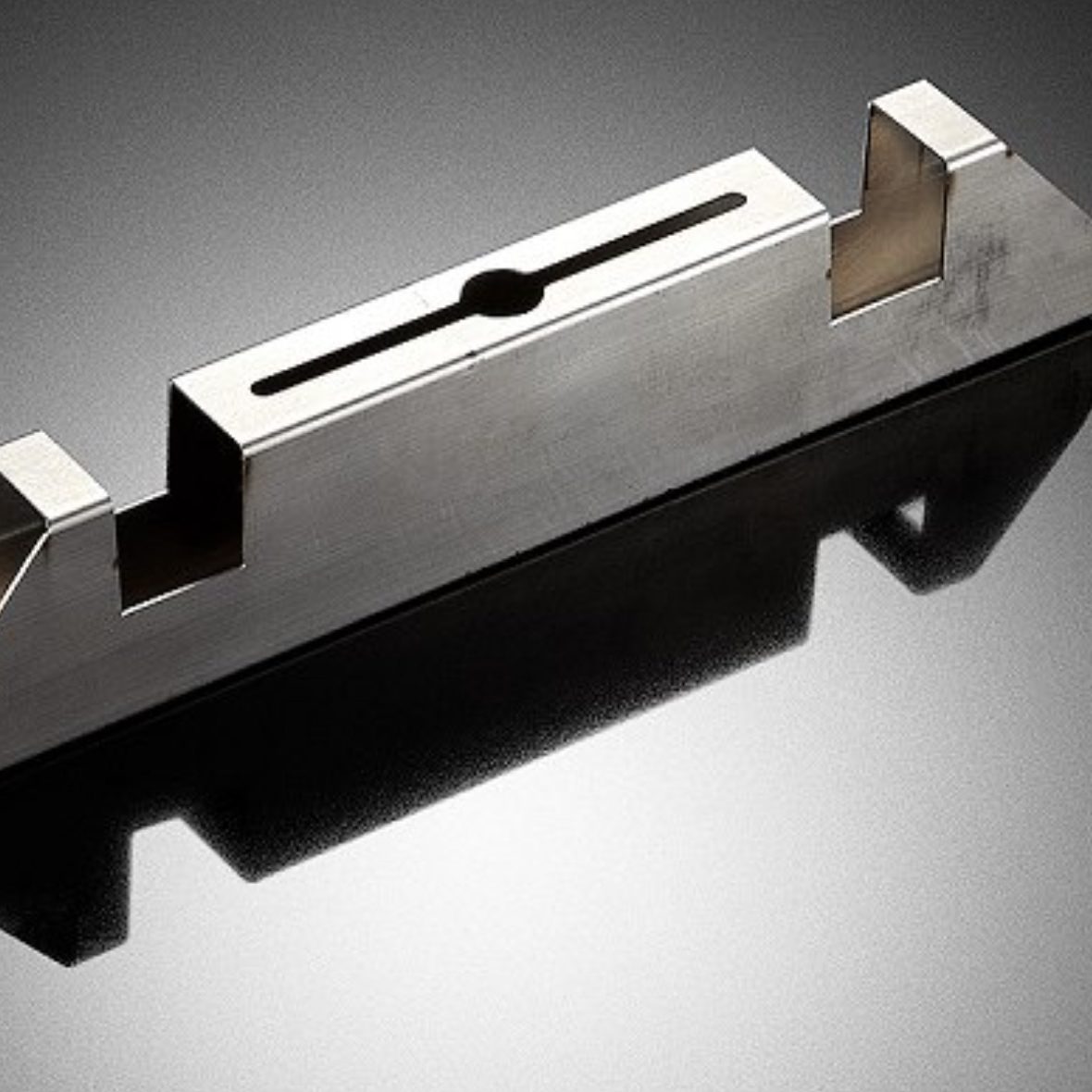

Laser Cutting

LASERLOGY, develops and manufactures a wide range of laser cutting machines and robots specially designed for 2D and 3D industrial applications. All common materials of the industrial machining (from steel, aluminum, stainless steel or other metals to non-metallic materials such as plastics, leather, wood or ceramics ) can be laser-cut with high quality and safely. With this technology, a wide range of material thicknesses can be cut, from 0.5 mm to more than 30 mm. This broad spectrum of materials makes lasers the best cutting technology for a large variety of applications.

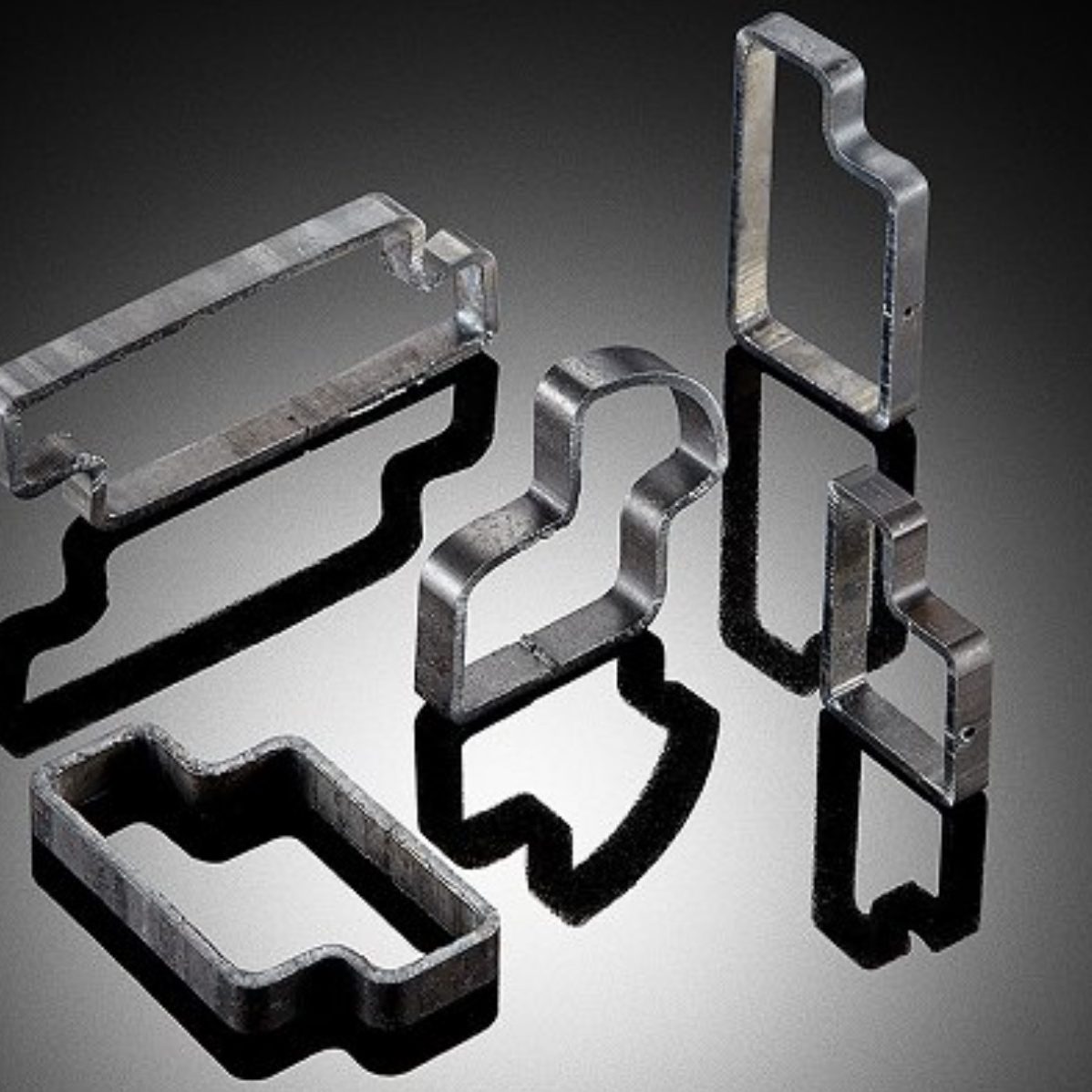

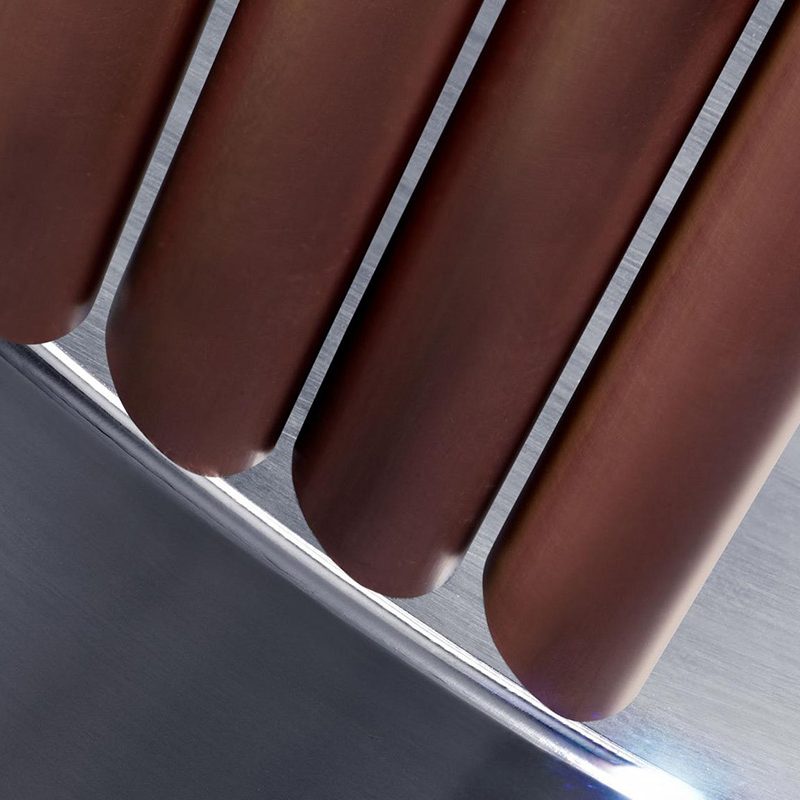

Laser Welding

LASERLOGY, offers its customers laser welding robots and machines with the latest technologies in the industry. The laser beam offers different possibilities for joining metals. This technology allow joining parts by their surface or generating deep weld seams. The laser welding can be combined with conventional welding procedures and it is also possible to weld using a filler material. Lasers can weld metals that have a high melting temperature and high thermal conductivity. Due to the highly concentrated energy and the short duration of the process, complex welds can be performed at high speed.

Laser Marking Applications

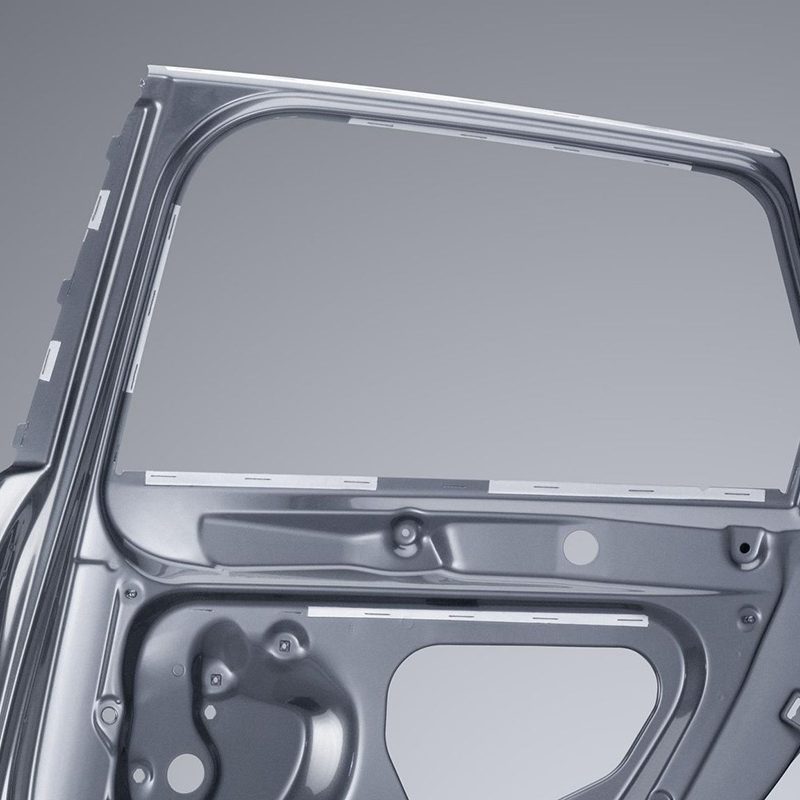

Laser Cutting Applications

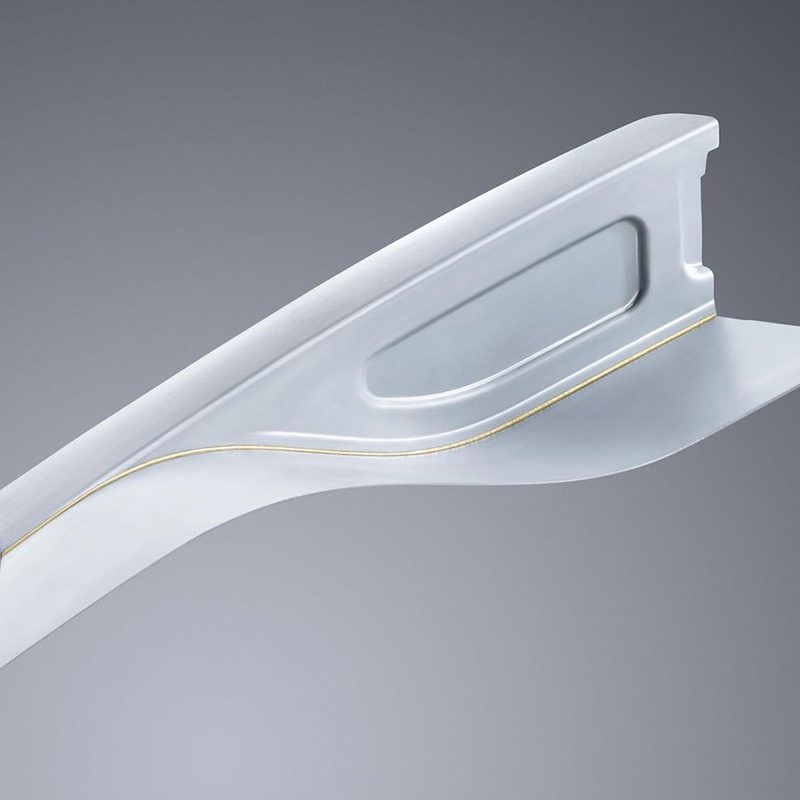

Laser Welding Applications

OUR PARTNERS