Laser marking, a non-contact marking procedure.

Laser marking is one of the most used and widespread applications of laser technology today. The amount of objects that we usually use and that have been marked by laser is enormous, even if we do not realize it. Being able to go from the expiration date of some food, the letters of the computer keyboards or the identification codes of parts of any manufacturer. Despite being complex, the basis of laser marking can be summarized as the contribution of a large amount of concentrated energy aimed at a single small point on an object, which can oxidize, change color, burn or vaporize.

Laser marking advantages

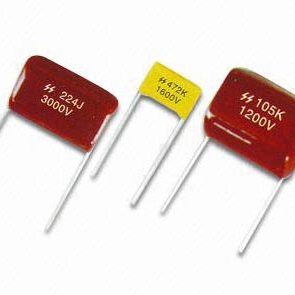

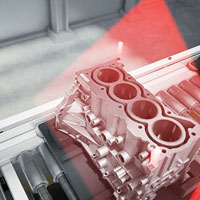

Wide range of materials

Due to the different laser technologies currently on the market (Fiber, CO2, UV, etc.), laser marking can work on all type of metallic materials (steel, aluminum, copper, brass, silver, gold, titanium, etc.) and, on a wide range of non-metallic materials (plastics, wood, stone, glass, paper, cardboard, ceramics, acrylic, etc.) used in the industry nowdays. This wide spectrum of materials, together with the high processing speed that can be obtained, makes the laser the marking method par excellence in the most demanding sectors.

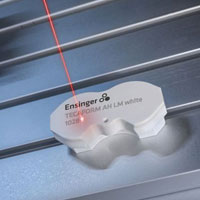

Non-contact marking and without consumables

One of the greatest benefits of laser engraving and marking is that it is a non-contact process. This means that the laser beam does not touch physically the material that it is being processed, but rather relies on heat to achieve the desired results. This is a great benefit over more traditional methods, because it eliminates the abrasion damage that historically often occurred to materials, as well as wear on the engraving tool. Being a process free of consumables makes maintenance costs almost non-existent, increasing the profitability of your company.

High efficiency and quality

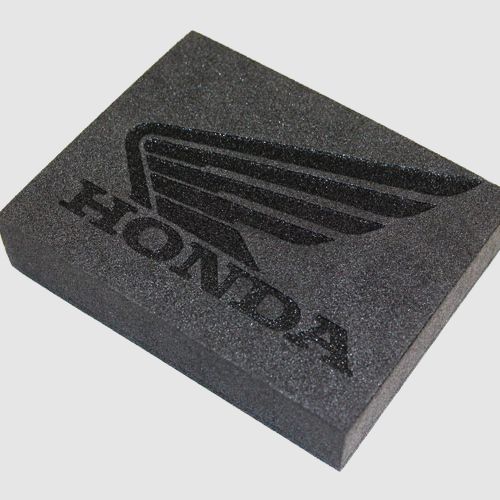

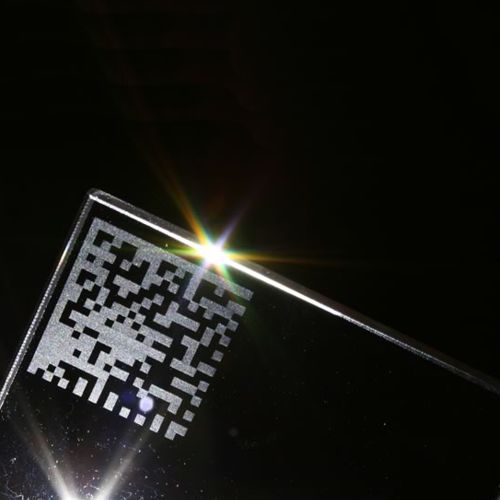

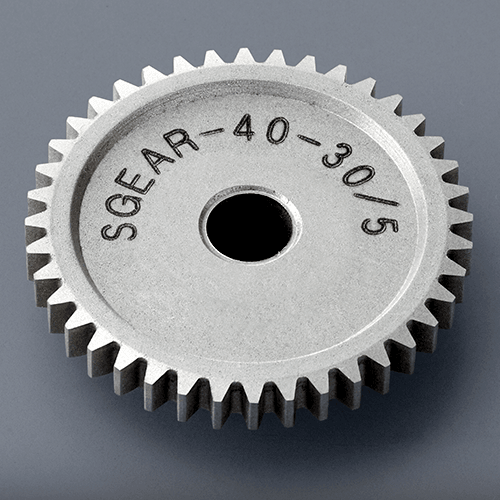

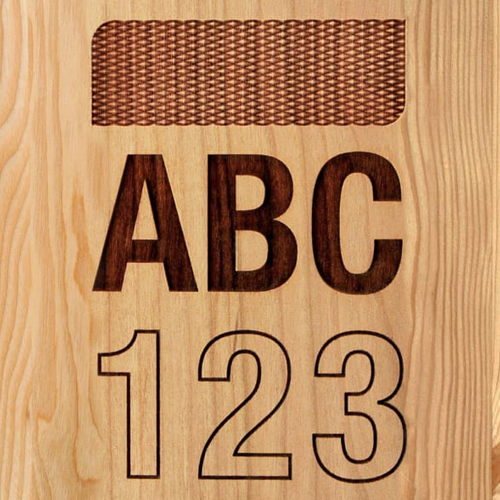

While companies must seek processes that are efficient, they must also focus on quality. Looking for methods that are efficient and provide the necessary results at the same time can be difficult, but laser marking can achieve this goal easily. The markings obtained are clear, legible and permanent, furthermore, they can be easily read by both humans and machines. They are perfect for all type of applications, whether it’s creating aesthetically appealing customization markings or creating traceability codes for machines to scan. Laser marking ensures that quality is never sacrificed.

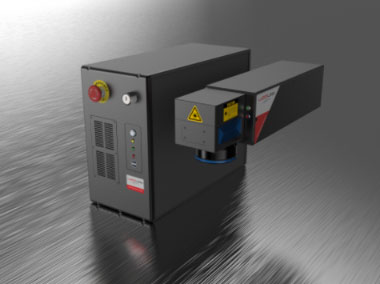

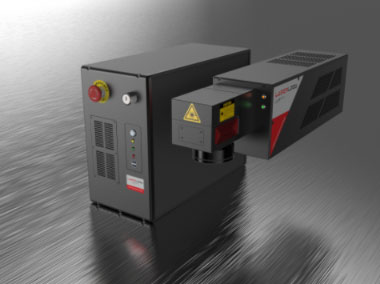

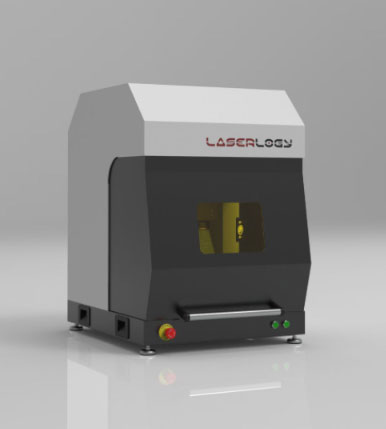

Laser marking systems range

LASERLOGY offers you a large selection of laser markers with multiple power variants and with all the usual industry wavelengths: Fiber (1064nm), CO2 (10600nm) and UV laser (355nm). These systems are the best choice for marking and engraving processes on a wide range of materials, such as: metals, plastics, wood, cardboard, paper, glass, stone, acrylic, ceramics, fabrics, etc. Its compact dimensions and advanced control possibilities make these laser markers the best choice for the most demanding industries, such as automotive, aeronautics, machinery, pharmaceuticals, electronics or packaging.

LS-F Series

Laser markers with fiber laser technology with up to 50W of power for marking all type of metals and a wide range of plastics. Compact and robust systems that allows its use in the most aggressive industrial environments.

LS-C Series

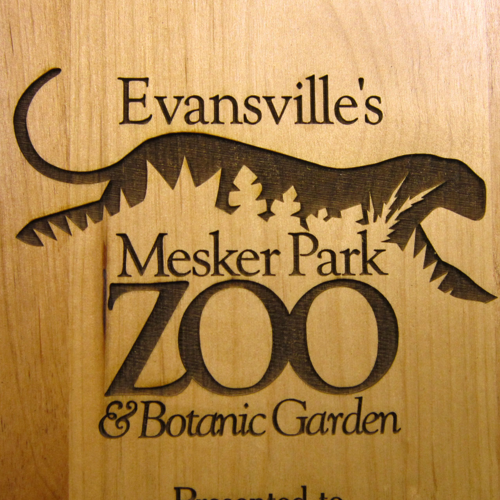

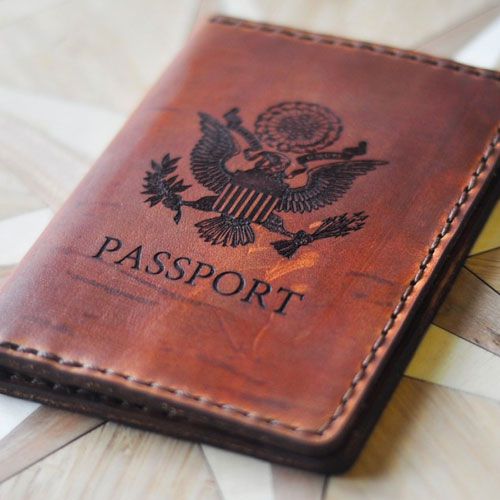

Laser markers with CO2 laser technology with up to 30W of power for marking coated metals and non-metallic materials, such as: wood, paper, cardboard, stone, glass, leather, fabrics, acrylic, etc.

LS-UV Series

Laser markers with DPSS laser technology and UV wavelength (355nm) for marking sensitive materials to thermal damage. These systems are ideal for marking glass, silicones, sensitive plastics, or surgical tools.

Customized laser solutions

In an industrial sector characterized by business concentration and the standardization of products and services, the offer of flexible solutions and personalized customer service are two fundamental assets for the development of the companies . At LASERLOGY, we are passionate about providing a close professional treatment, based on strict quality standards. We are constantly evolving and we adapt every day to market demand, providing tailor-made solutions for a customer that know he want. In short, we are walking in the same direction to grow together, innovating, attending to market trends and the needs of each company, and demanding ourselves more every day, to optimize the solutions that we provide to each client.

Application samples