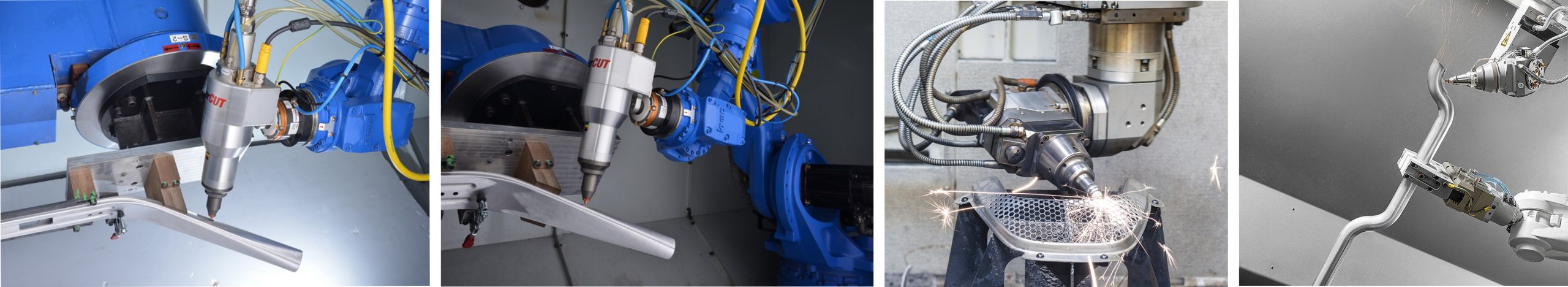

Laser cutting, a non-contact cutting procedure.

Laser cutting is a separation process with which metallic and non-metallic materials of different thicknesses can be cut. It is based on a laser beam that is guided, shaped and focused. When it strikes the part, the material heats up so much that it is melted or evaporated. All the laser power is concentrated in a point whose diameter is usually less than half a millimeter. If more heat is concentrated at this point than can be removed by heat conduction, the laser beam passes through the material completely, thus beginning the cutting process.

Laser cutting advantages

Wide range of materials

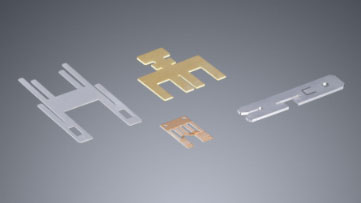

All common industrial machining materials (from steel, aluminum, stainless steel or metal sheets to non-metallic materials such as plastics, glass, wood or ceramics) can be laser cut safely and with high quality. With this technology you can cut a wide range of thicknesses, from 0.5 up to 30 millimeters. This wide spectrum of materials makes the laser the best cutting tool for multiple applications with metallic and non-metallic materials.

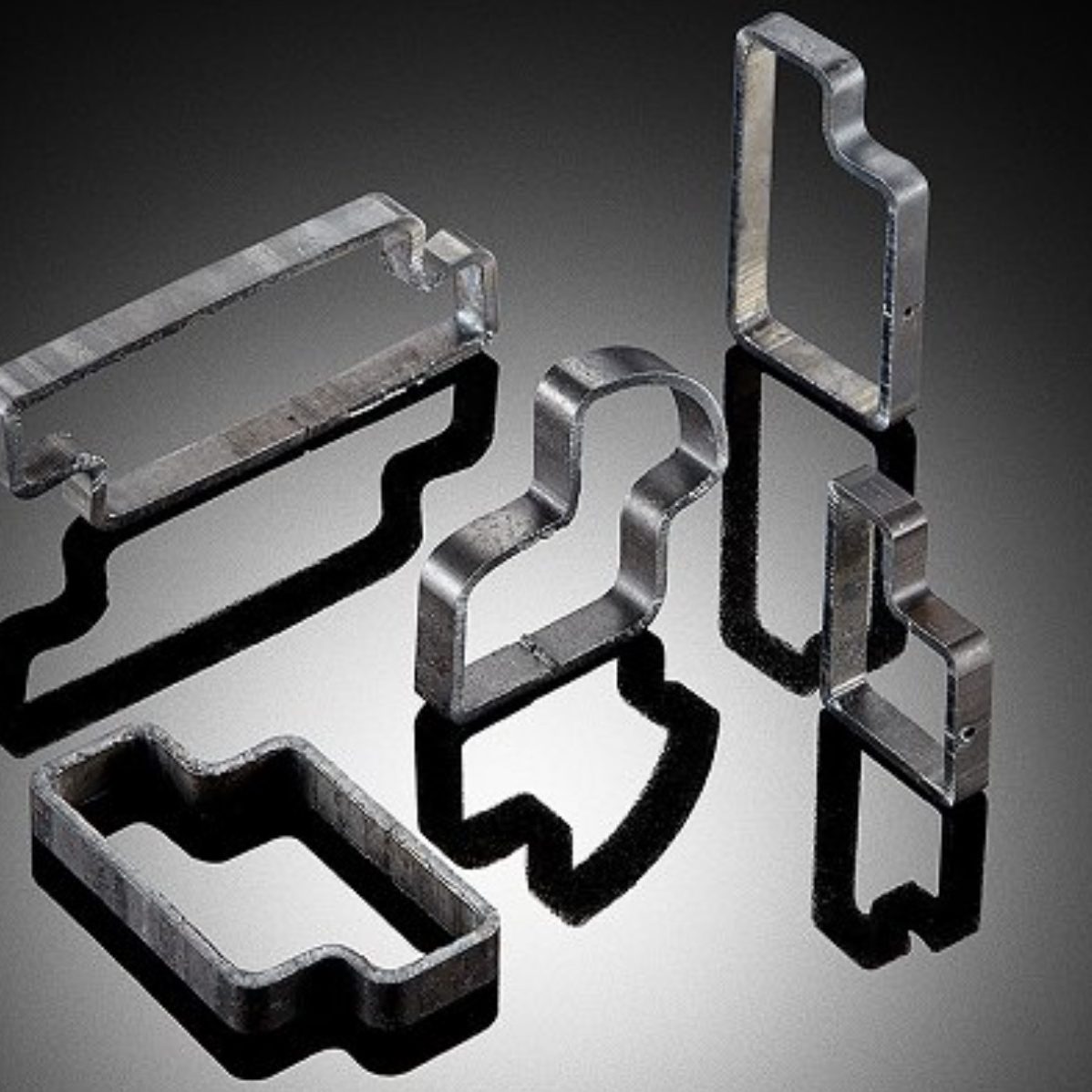

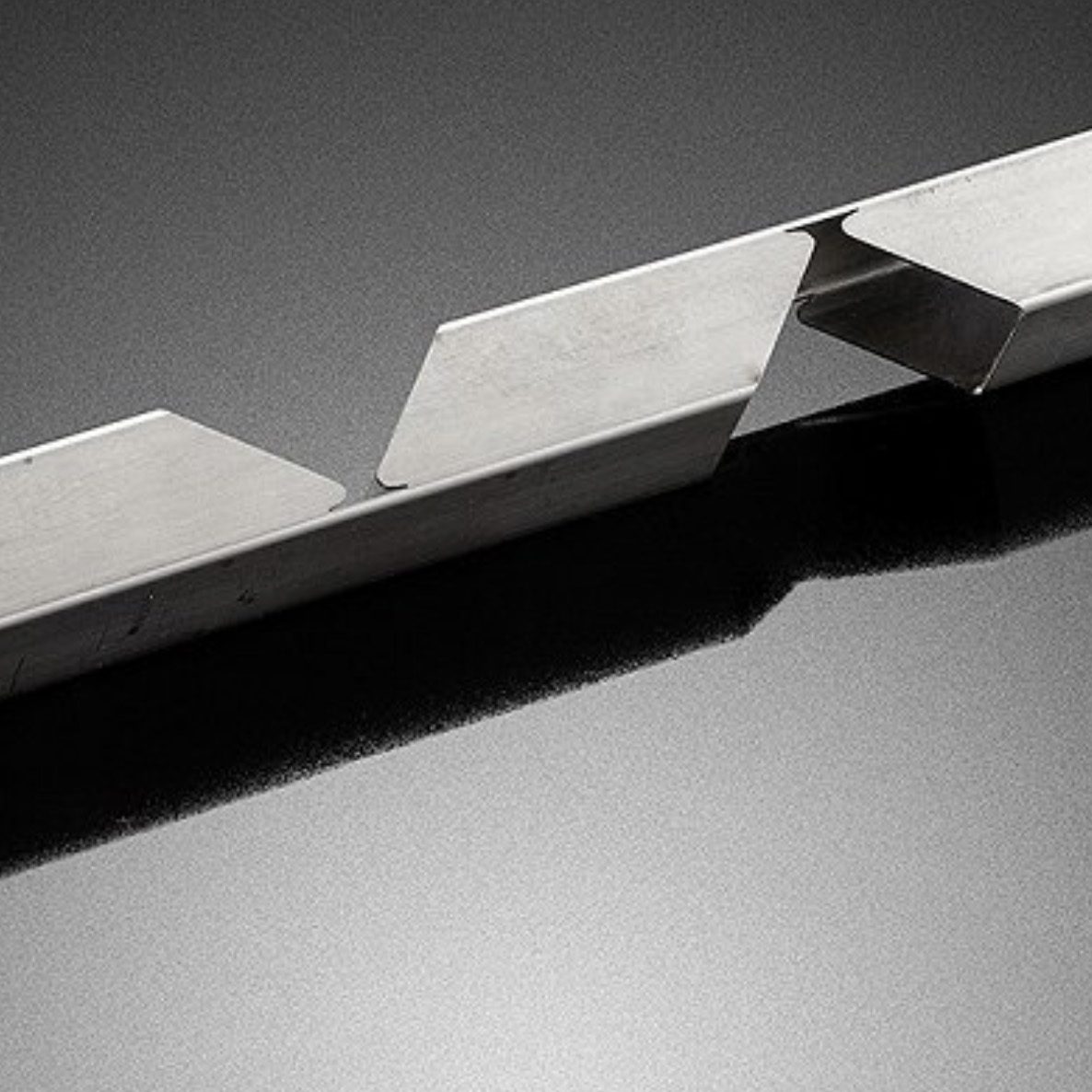

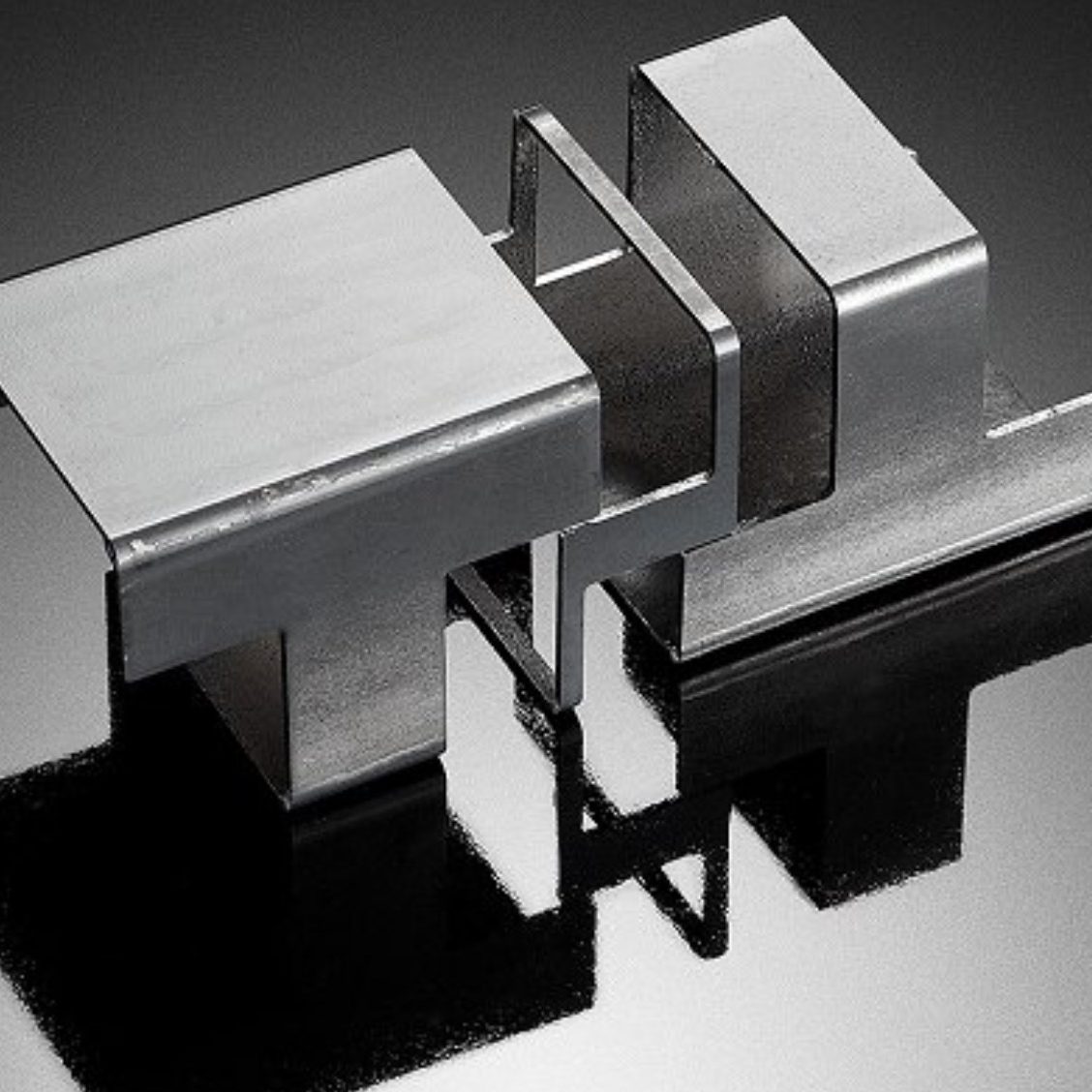

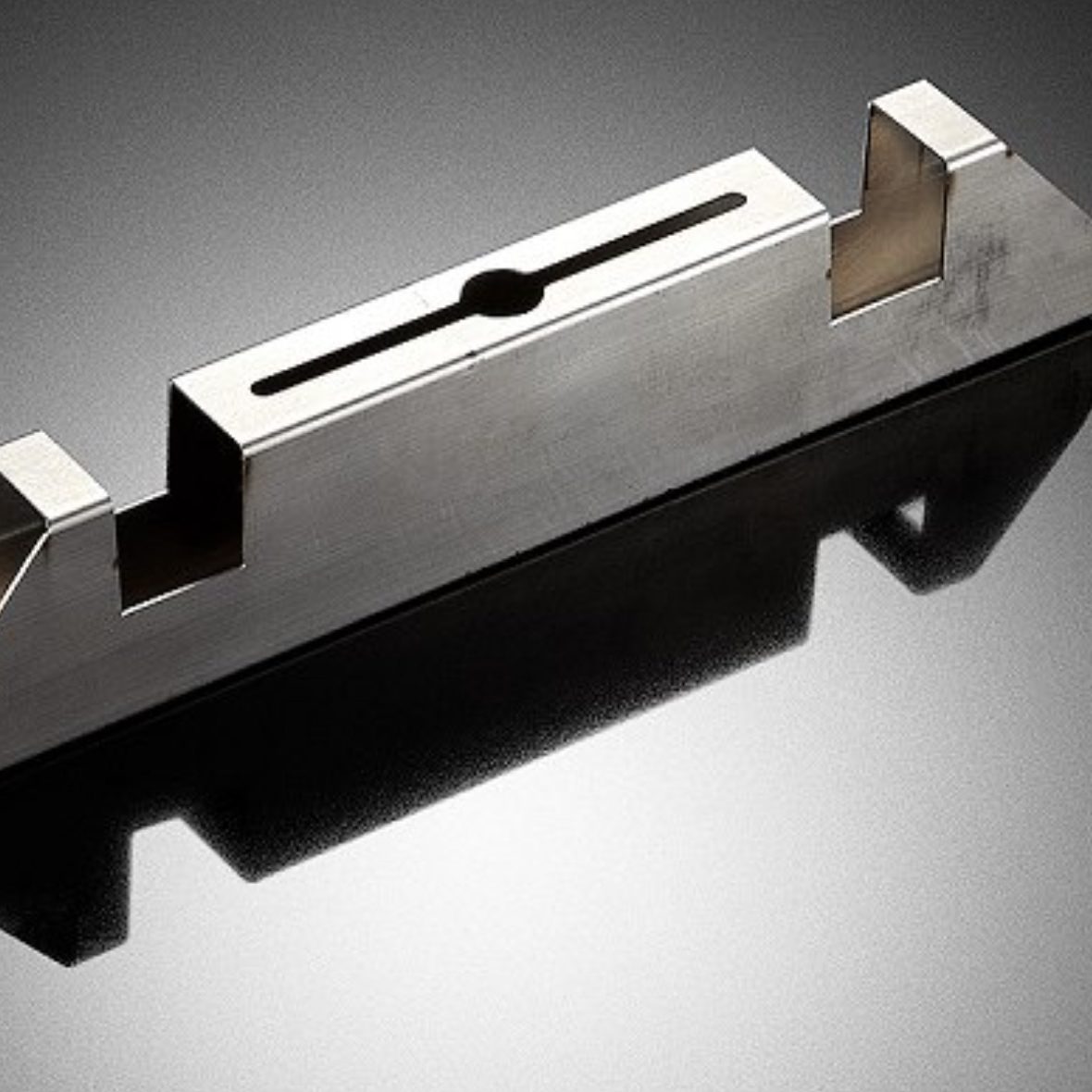

Contour freedom

The concentrated laser beam heats the material only locally, the rest of the part only receives minimal or no thermal load. In this way, the width of the cutting groove hardly exceeds the beam diameter and even complex and intricate contours can be cut smoothly and without burrs. In most cases, costly finish machining is no longer necessary. Due to its flexibility, this cutting procedure is used especially when batch sizes are small, when variants abound, and for prototyping.

High quality cutting edges with ultrashort pulsations.

Ultrashort pulse lasers evaporate almost any material so quickly that no thermal influence is observed. Thus, high-quality cutting edges are generated without the appearance of casting. Therefore, lasers are especially suitable for the manufacture of the most intricate metallic products such as “stents” in medical technology. In the display industry, ultrashort pulse lasers cut chemically hardened glass.

Customized laser solutions

LASERLOGY, develops and manufactures a wide range of laser cutting machines and robots specially designed for 2D and 3D industrial applications. In an industrial sector characterized by business concentration and the standardization of products and services, the offer of flexible solutions and personalized customer service are two fundamental assets for the development of the companies . At LASERLOGY, we are passionate about providing a close professional treatment, based on strict quality standards. We are constantly evolving and we adapt every day to market demand, providing tailor-made solutions for a customer that know he want. In short, we are walking in the same direction to grow together, innovating, attending to market trends and the needs of each company, and demanding ourselves more every day, to optimize the solutions that we provide to each client.

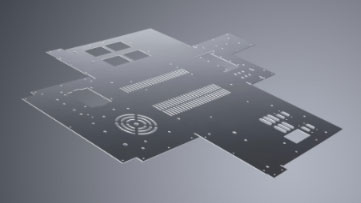

Application samples